Main products: steel pipe, steel coil, steel plate, profile steel and pipe fittings. Other steel products can also provide one-stop service.

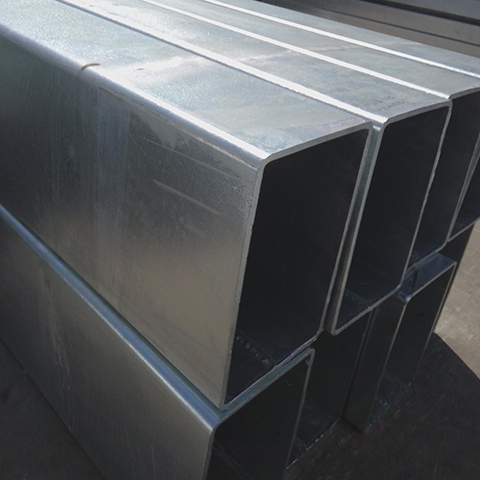

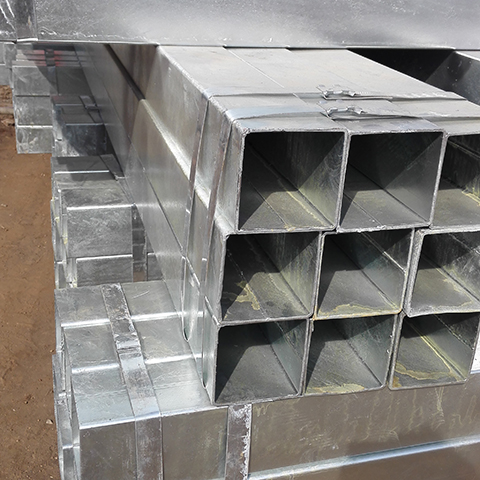

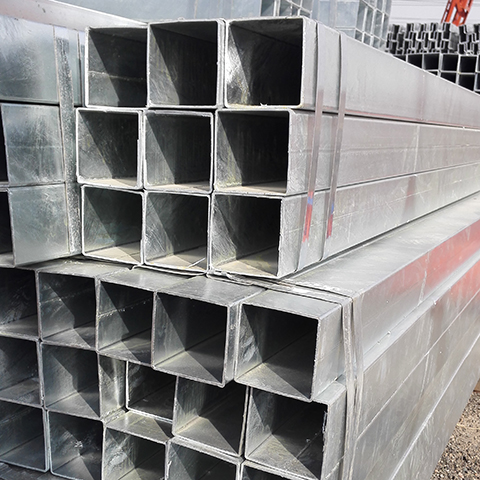

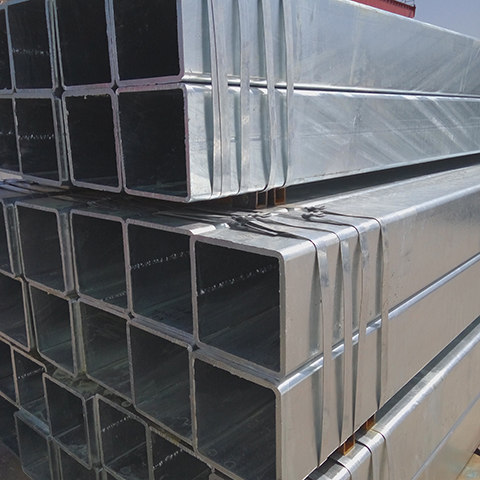

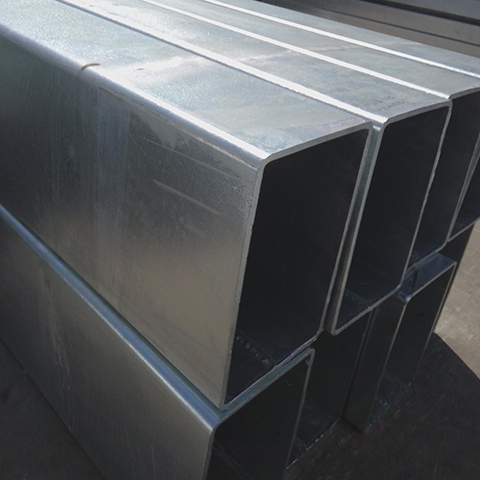

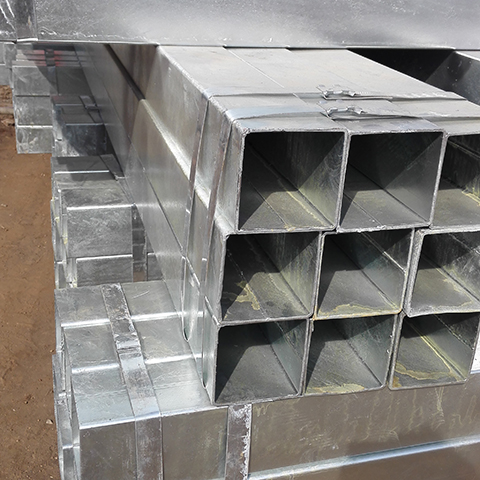

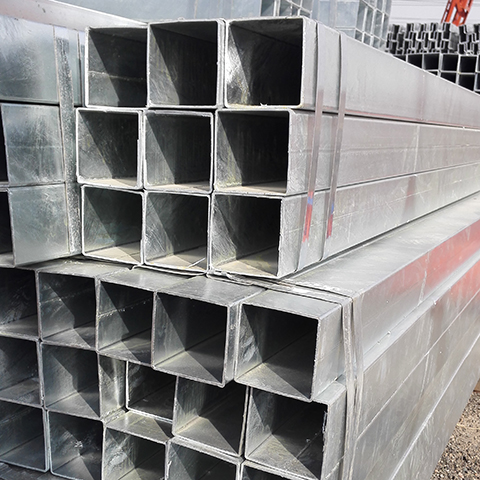

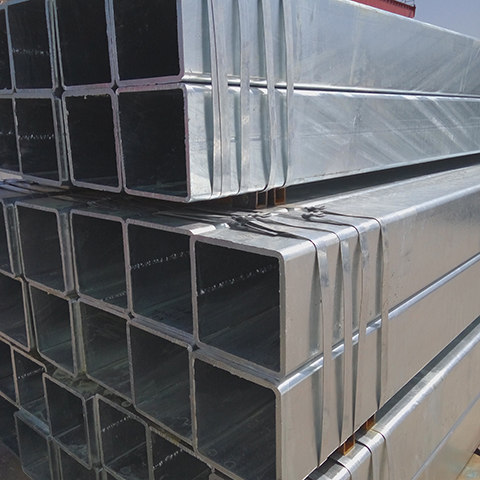

Hot dipped galvanized hollow section

|

Length of a side |

15mm-500mm |

|

Wall Thickness |

1mm-12mm |

|

Length |

250mm-12000mm |

|

Material |

SPHC,Q195,Q215,Q235,Q345,SAE1010,SAE1020 or relative |

|

Zinc Coating |

220g/m2-800g/m2 |

|

Standard |

GB/T3091,EN10219,EN10210,ASTM A53 |

|

Certification |

ISO9000 |

|

Technique |

ERW,HFW |

|

Packaging |

Loose, plastic package, black strips, G.I strips |

color:

1. G.I hollow section

2. Main application: construction bridge building, electricity tower, advertisement pole, underground water transfer, roof structure

3. Material: SPHC, Q195,Q215,Q235,Q345,SAE1010,SAE1020 or relative

1. G.I hollow section

2. Hot dipped galvanized rectangular steel pipe

3. Hot dipped galvanized square steel pipe

Place of Origin: China

Brand Name: Jinnuo

Certification: ISO9000

Minimum order: 10MT

Price: 560USD/MT – 760USD/MT

Packing Details: Loose, plastic package, black strips, G.I strips

Supplying Ability:2000MT-7000MT per Month

Hot dipped galvanized Hollow section

Hot dipped galvanized Hollow section is the main structural material in construction like bridge building, electricity tower, advertisement pole, underground water transfer, roof structure. It will be manufactured by ERW & HFW. The fabrication process by hot dipped zinc coating thickness is 220g/m2-800g/m2, The main advantage is the zinc coating will be the big thickness, anticorrosive is good. Normal usage validity time will be around 25-50 years. The pipe can be used in adverse environment, like strong acid, wet, high temperature etc. Also it can be thread and coupling at the two ends the standard are ASTM and BS.

Production Process

1: Inspection Raw material in site

2: Open Coil and Joined welding

3: Continuous ERW or HFW welding

4: Cutting

5: End and welding inspection

6: Mark Packing and Trucking